The Victorians

Barnstone Cement Works

↑ On the left Barnstone and the cement works in 1899.

On the right, the present day - the village and the cement works have got bigger. ↑

Now this is strange!

The name of the village was originally Barnston but it was spelled as Barnstone (with an 'e') throughout the 19th century. This was corrected back to Barnston in 1888.

The Barnstone cement factory opened in 1864 and they used a picture of a barn with a millstone as the company logo. This appeared on their cement bags with the name Barn-stone Cement. The company managed to get the name of the village changed back to Barnstone in 1905.

There has been an industrial site at Barnstone since 1864, where Blue Lias limestone was dug out of the ground to make lime in 16 bottle kilns. Lime is widely used to purify steel and to make mortar and cement for building.

The works began to make cement in 1885, using one of the first rotary kilns in the UK. It was a clever idea, even though the machine did not work properly. That first kiln has been kept by the factory as a piece of industrial heritage. A year later eight of the bottle kilns were used to make cement.

From 1969 the works was called Barnstone Special Cements and was a research facility staffed by geologists, metallurgists, mechanical engineers, process engineers, chemical engineers and many others. In 1983 specialist cements were made for the mines and tunnels. In 2006 the 1930s' kiln was shut down - it had been working for three quarters of a century. The plant then turned to grinding, blending and packing cement which it does to this day.

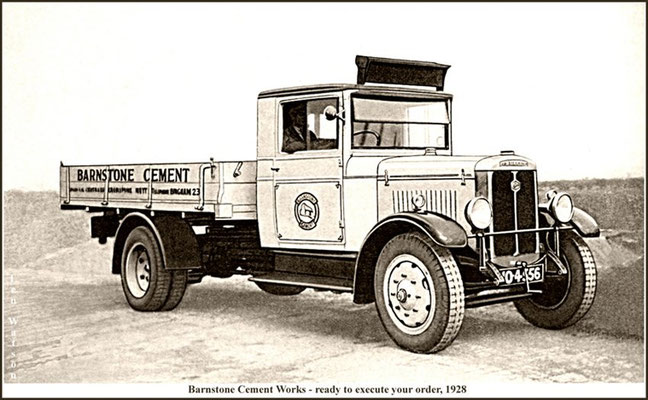

↓ Below: photographs from the 1930s

This locomotive at the Barnstone Cement Works was called 'Langar'. Photograph reproduced courtesy of the Railway Correspondence and Travel Society RCTS Britain's leading organisation for people interested in all aspects of railways past, present and future.

Now, 72 people work at the plant which produces 230,000 tonnes of cement every year. Most is sold to builders and DIY-ers, as well as specialist cement for building tunnels.

↓ Below: photographs from the present day

Digging holes in the ground to take out minerals such as limestone leaves a mess. The earliest quarries at Barnstone have now been filled in and grassed over. Later quarries filled up with water and have been left as lakes. Work has been done by Barnstone Lakes Ltd to turn them into fisheries.

↑ Images from the Barnstone Fisheries Ltd website.

Working with the local community

Lock 15 at Woolsthorpe was completely rebuilt. The company organised the pouring of 400 cubic metres of specialist concrete into Lock 15 whilst a team of the volunteers, including workers from the Barnstone Cement, built up the walls.

The Grantham Canal opened in 1797, was out of use by 1929 and was officially abandoned in 1936 but, for the past 30 years, a group of volunteers has been working to restore it.

(For more on the Grantham Canal, click here.)

Working with the local community

The Wiggly Waggly Way

Langar Primary School’s Eco Club visited the Barnstone Cement Plant to unveil new signs with the name of the community footpath around the works: ‘The Wiggly Waggly Way’. It was Kate from Class 4 who came up with the winning entry in a competition to name the footpath.

Their visit to the plant was an opportunity for the 13 Eco Club pupils to learn more about how the company minimises its waste, by sending nothing to landfill. This included the plant’s environment and health and safety co-ordinator Josie Morrissey running an interactive quiz to find out how much they had learnt about recycling.

All pupils received their very own bird box from the plant to put in their garden to encourage more birds to nest locally.

Article in 'The Melton Times' 2015

If you were here 200 million years ago, you would have seen these

at Prehistoric Barnstone

During the Jurassic period much of Britain lay at the bottom of a shallow tropical sea swarming with life. And evidence has been found here at Barnstone. Workers at the quarry unearthed the bones of two types of sea dinosaurs that swam here 200 million years ago.

Left: ichthyosaur - length 2 metres, weight 100 kg, diet fish.

Right: plesiosaur - length 5 metres, weight 500 kg, diet fish and shellfish.